+6085-644 350 / +6017-302 3744

DMT@d-majuteknik.com

Lot 6107 & 6108, Phase 5, Bandar Baru Permyjaya

Vermeer Process excels in process filtration. As a designer, trouble-shooter, manufacturer, and supplier, we are equipped to advise, design, and deliver the perfect service or product throughout your projects. For us, effective filtration involves considering filter efficiency, lifespan, and the price-quality ratio. Another important aspect is reducing maintenance costs. More focus on maintenance leads to less costly downtime. By assessing and lowering total ownership costs, we make process risks more transparent.

The range of products that Vermeer Process Technology designs and fabricates includes filters, strainers, self-cleaning filters, flow equipment, and specially developed custom solutions. Key attributes of all our products are filter efficiency, extended lifespan, price-quality ratio, and reduced maintenance costs by minimizing downtime. Vermeer Process Technology has expertise in working with almost any exotic material imaginable.

Vermeer Process offers filtration solutions and services for:

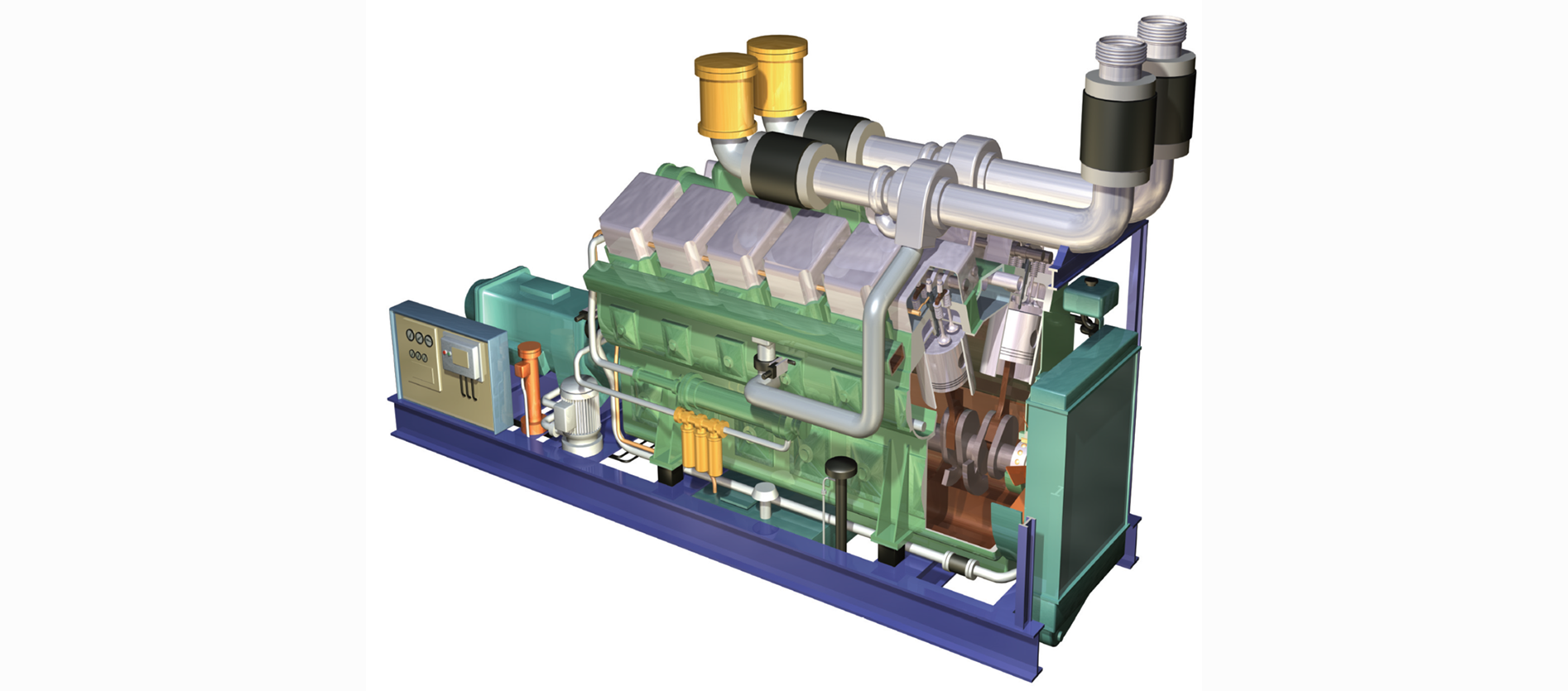

AMOT is the leading designer, developer, and manufacturer of safety products and solutions for critical rotating equipment operated in hazardous areas. This equipment encompasses engines, compressors, and turbines.

AMOT's product families include valves, electronic and pneumatic instrumentation, control and condition monitoring systems, and hazardous area safety products.

AMOT provides control and safety solutions for a wide variety of applications, supported by its extensive experience and in-depth capabilities, including custom engineered solutions to meet specific customer requirements. We offer solutions for diesel engines, engine control and monitoring, compressors, turbines, marine, hazardous areas, and many other applications.

AMOT products are extensively installed and utilized in various industries, including oil and gas, power generation, marine, transportation, mining, and many others.

Procedyne Engineers are renowned for their strainers, which are a vital part of any processing system. Strainer filters serve as an economical safeguard, protecting essential equipment like pumps, heat exchangers, and flow meters from harmful particles. Procedyne strainers are widely used across the steel, chemical, power, oil, paper, and wastewater treatment sectors. With over 50,000 installations, Procedyne's strainers are proven performers, trusted for all types of straining needs.

Procedyne provides a variety of Y Type Strainers, Basket Strainers, Duplex Strainers, and Automatic Strainers in sizes from ¼” to 24”. Their engineering team can customize strainers to meet your specific requirements. Available body materials range from Cast Iron, Cast Steel, Stainless Steel, Alloy 20, GRP/FGP, Bronze, to exotic materials such as Monel, Hastelloy, Super Duplex Stainless Steel, and Titanium.

Procedyne Engineers have satisfied customers worldwide in industries including oil & gas, petrochemical, and power generation.

Holland Marine Services Amsterdam B.V. designs, produces, and supplies compact Biological Sewage Treatment units, Grease Separators, Grey Water tanks, Ejector type Vacuum Toilet systems, and is a provider of Reverse Osmosis Fresh Water generators, UV disinfection units, Hydrophore units, and Jets Vacuum Toilet systems.

To address current demands while maintaining design flexibility, Holland Marine Services Amsterdam has developed an innovative new line of Biological Sewage Treatment systems.

HMSA supplies shipyards and ship owners worldwide through a network of agents for various projects, ranging from Multi-Purpose Container vessels to Houseboats in Nigeria and from FPSOs to Luxury Super Yachts.

Lloyd’s Register of Shipping and The Netherlands Shipping Inspection granted Type Approval following an extensive long-term testing period.

The PETSEA RO series by Peter Taboada is a comprehensive range of reverse osmosis systems designed to produce high-quality fresh water from seawater. With decades of expertise in water treatment technologies, Peter Taboada has established itself as a leader in designing reliable and efficient RO solutions for a variety of industries. The PETSEA RO series is designed to handle varying capacities, ensuring flexibility in meeting client needs. The product lineup includes compact models (SW-Y series) with capacities ranging from 1.8 to 20 m³/day, making them ideal for small to mid-sized installations. For larger-scale operations, the medium-size SW series offers production rates up to 200 m³/day. For even greater demands, the SW-RE series is built to deliver high production rates beyond 250 m³/day with modular configurations adaptable to available space. Each system integrates advanced features such as energy recovery devices, which significantly reduce power consumption and operating costs, making them both cost-efficient and environmentally friendly.

The versatility and reliability of PETSEA RO systems make them suitable for a range of industries and applications. The integration of advanced filtration mechanisms, such as sand and multimedia filters, ensures the removal of suspended solids and the improvement of overall water quality.

Peter Taboada's commitment to continuous innovation, supported by 30% of its workforce dedicated to R&D, ensures that each system is built to the highest standards. With over 40 years of experience in water treatment technologies and a presence in more than 40 countries, Peter Taboada provides robust, efficient, and reliable reverse osmosis solutions backed by a global network of expertise and support.

Experts in Oil in Water Analysis

Advanced Sensors consistently provides groundbreaking technology for Oil in Water analyzers. We integrate methods such as fluorescence, absorbance, and video microscopy with ultrasonic cleaning and optical spectrometry to guarantee analyzers deliver accurate readings dependably and consistently. Additionally, our skilled technical support team offers advice and assistance for all your oil in water monitoring requirements.

Measure Total Sulfur and Total Nitrogen with One Analyzer

NSure Sulfur: ASTM D5453, D6667, ISO 20846

NSure Nitrogen: ASTM D4629, ASTM D5176, DIN 38409, TEIL

27, EN 12225

NSure is our advanced total sulfur and total nitrogen analyzer that provides dependable and consistent measurements across a broad range, even during process fluctuations, and ensures close alignment with primary test methods. The updated technology of NSure offers ease of operation and maintenance. This innovative solution for gas, LPG, and liquid sample analysis is perfect for online monitoring in blending and refinery processes, as well as petrochemical, wastewater, and emissions monitoring. NSure maintains the proven durability of its predecessor, the 6200 model.

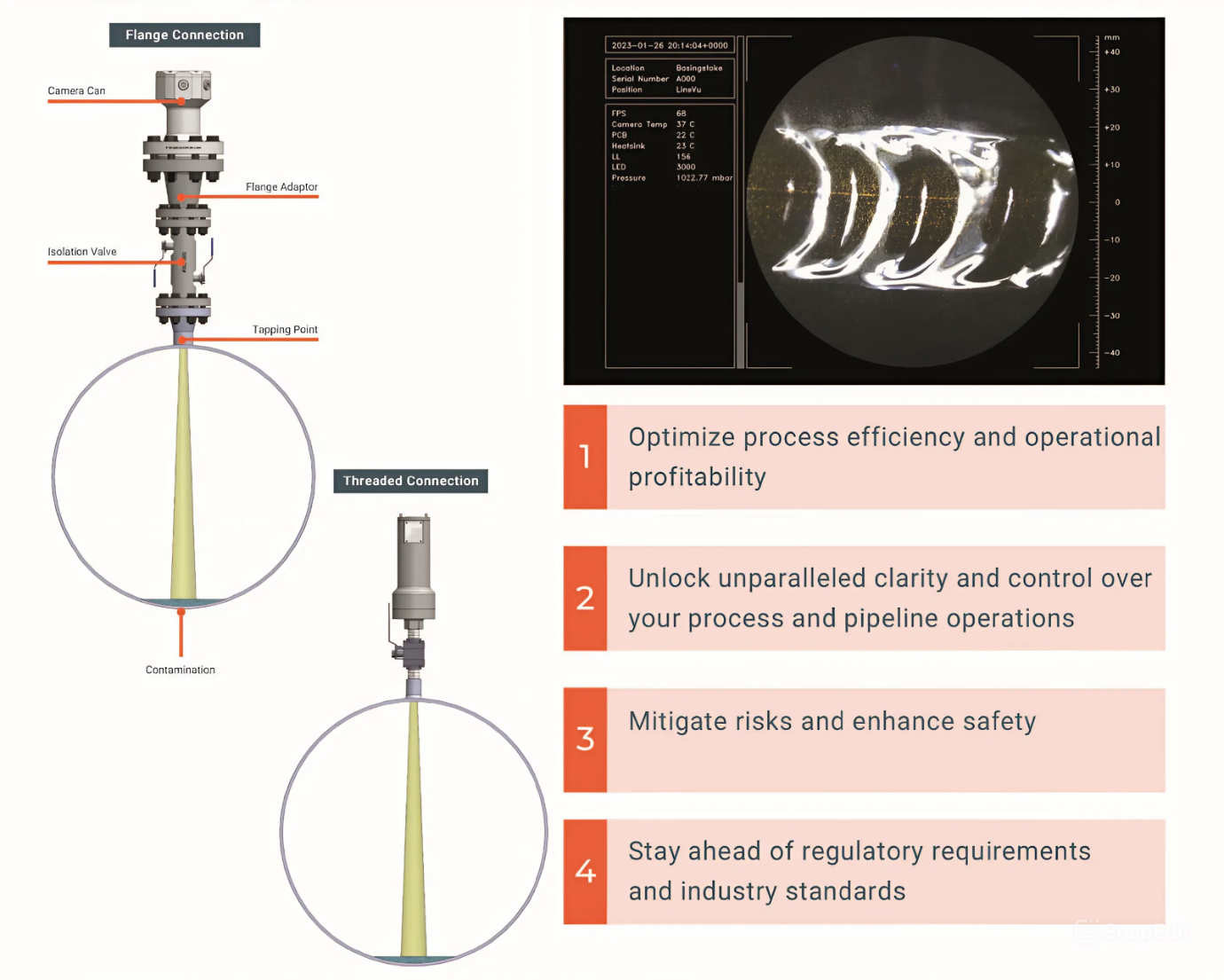

With the LineVu Discovery system, you can gain valuable insights by performing a liquid carryover study. This all-in-one, portable solution provides actionable information, helping you improve process efficiency in gas processing or ensuring the acceptability of gas at custody transfer points.

Throughout the study period, weekly review meetings are held to analyze the data collected and plan any flow ramping, flow switching, or multiple location testing. A comprehensive report at the end of the study period provides a review of the data, conclusions, and recommendations for further action.

Users have access to the LineVu Dashboard during the study, providing real-time access to videos and data analysis 24/7.

Conducting a liquid carryover study with the Discovery system is a cost-effective choice. You can evaluate filter performance and gas quality without a long-term commitment and with minimal costs. Once the relevance and severity of liquid carryover are understood, you can easily transition from the study to a fixed installation, ensuring uninterrupted data collection and consistent visual outputs. Technical Support and data analysis are also readily available.

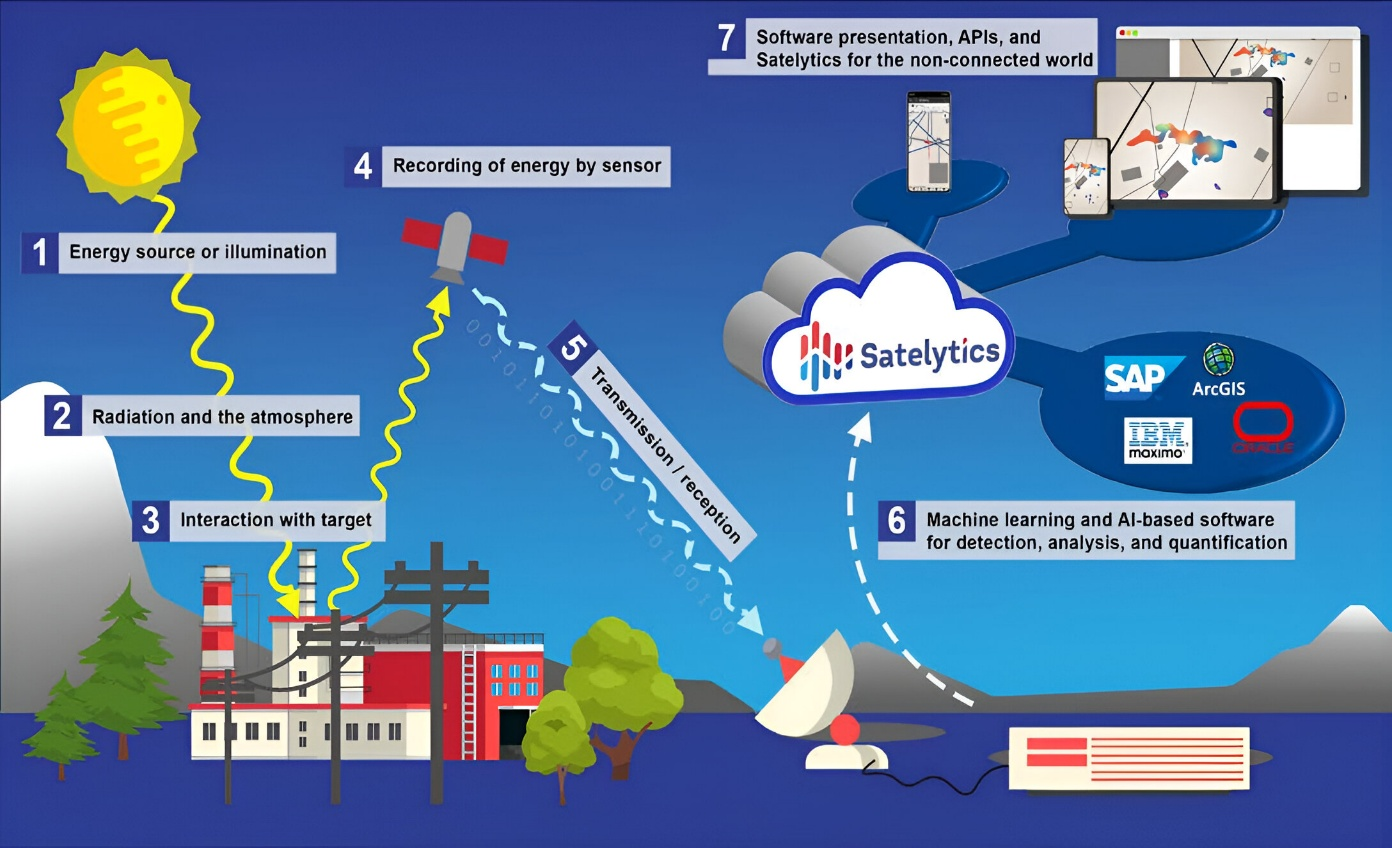

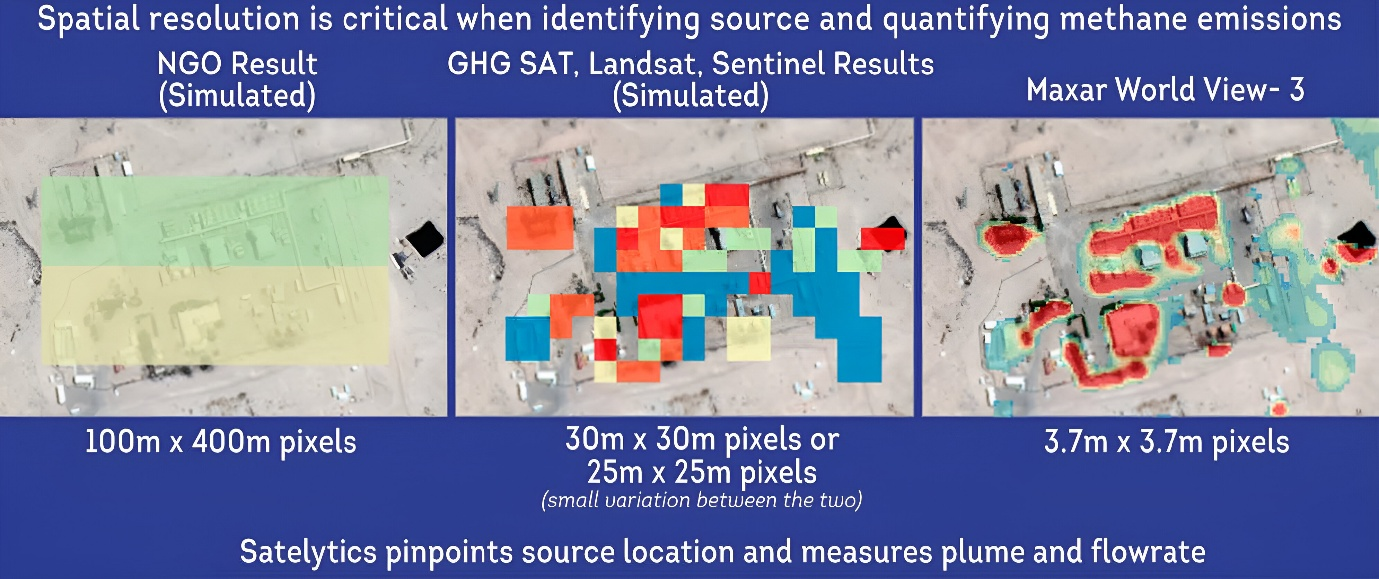

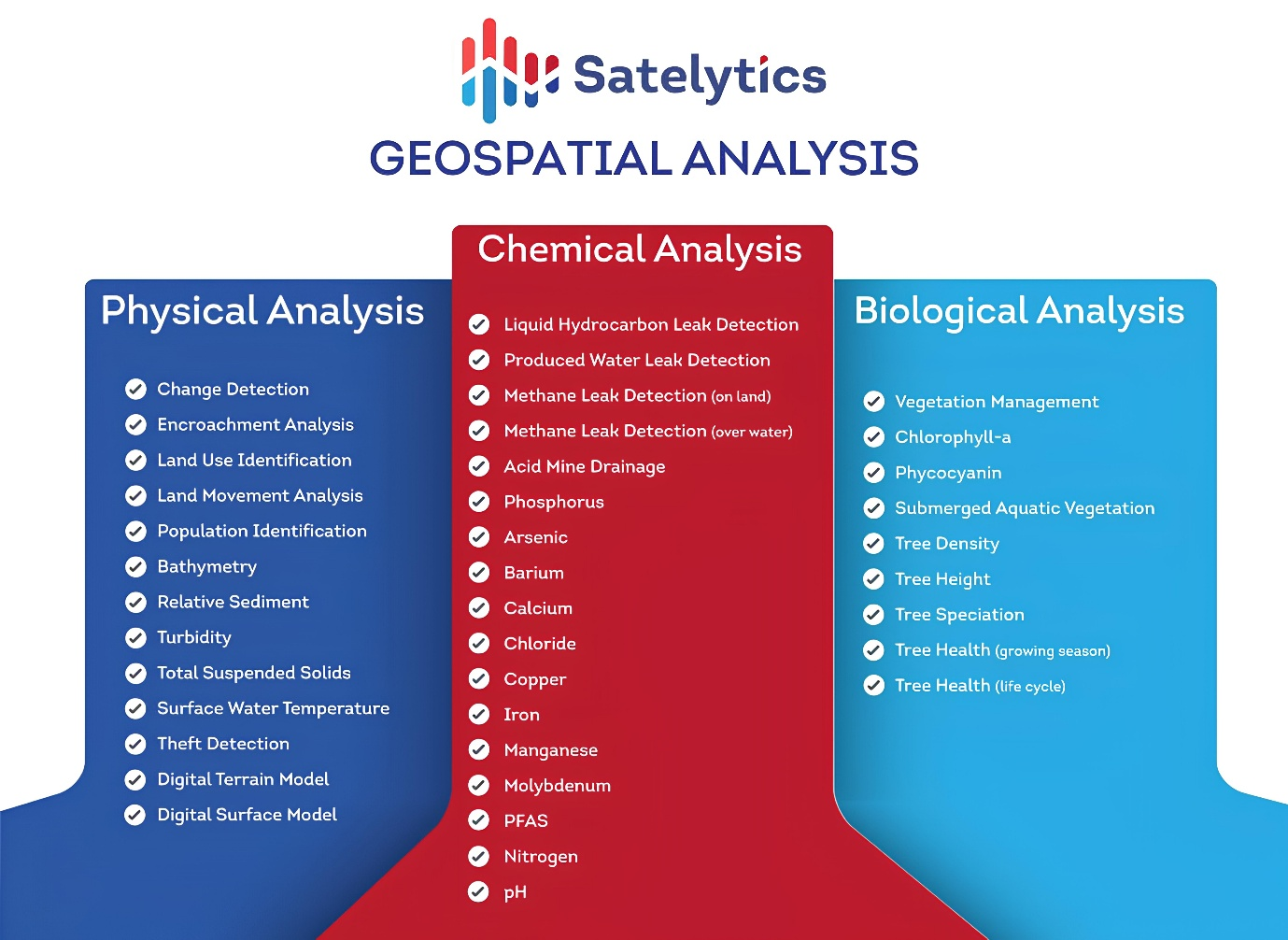

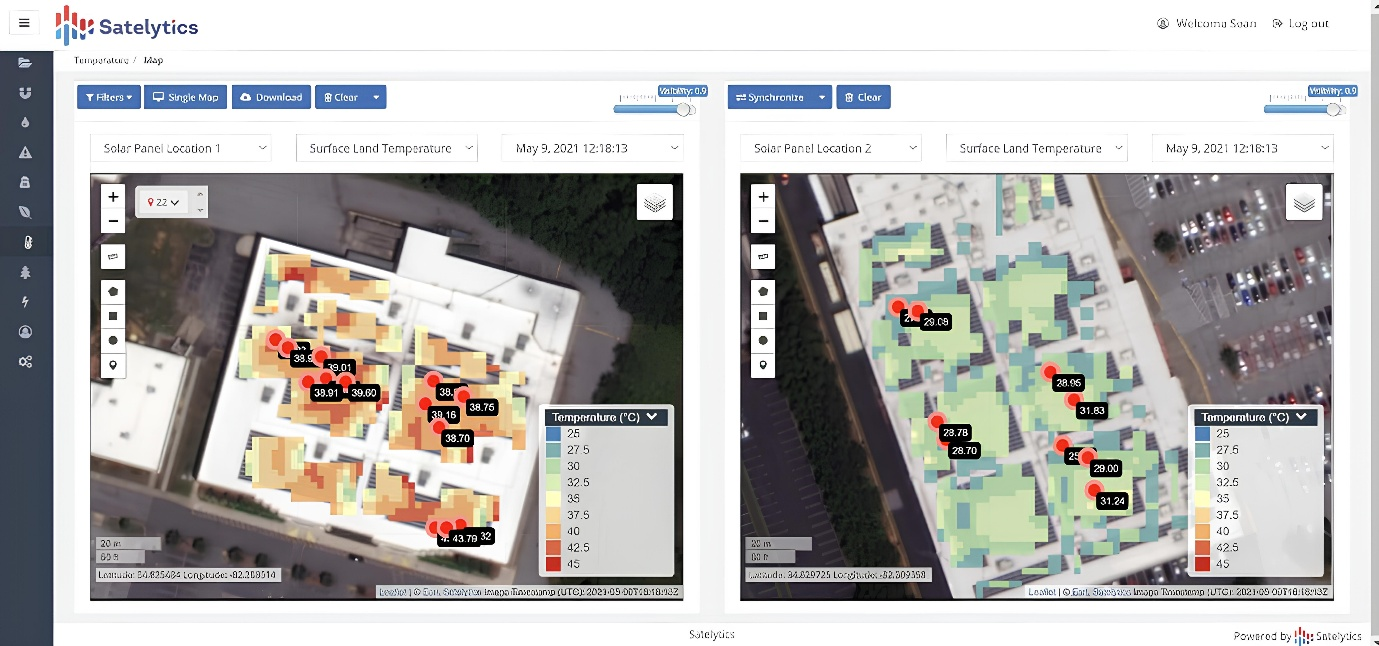

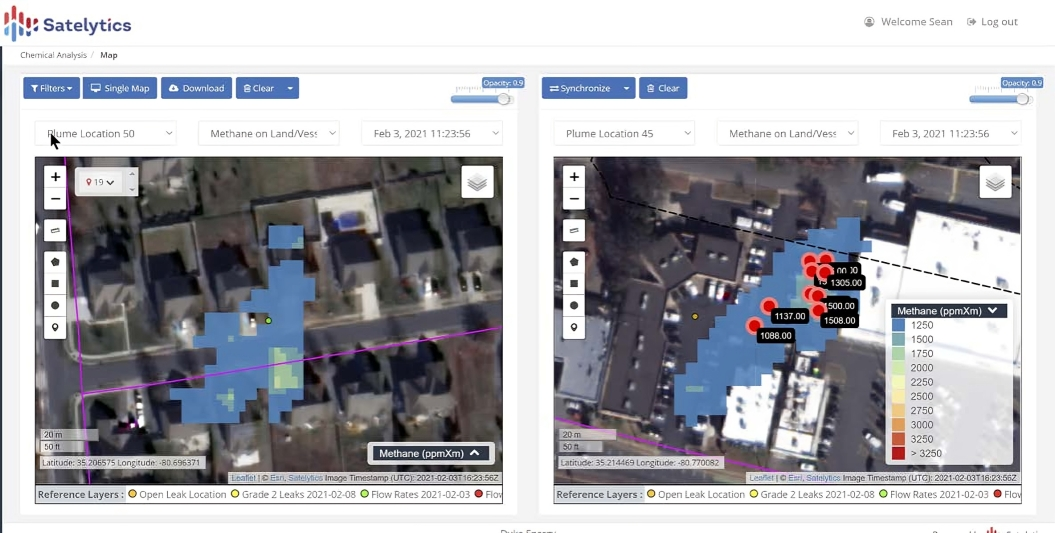

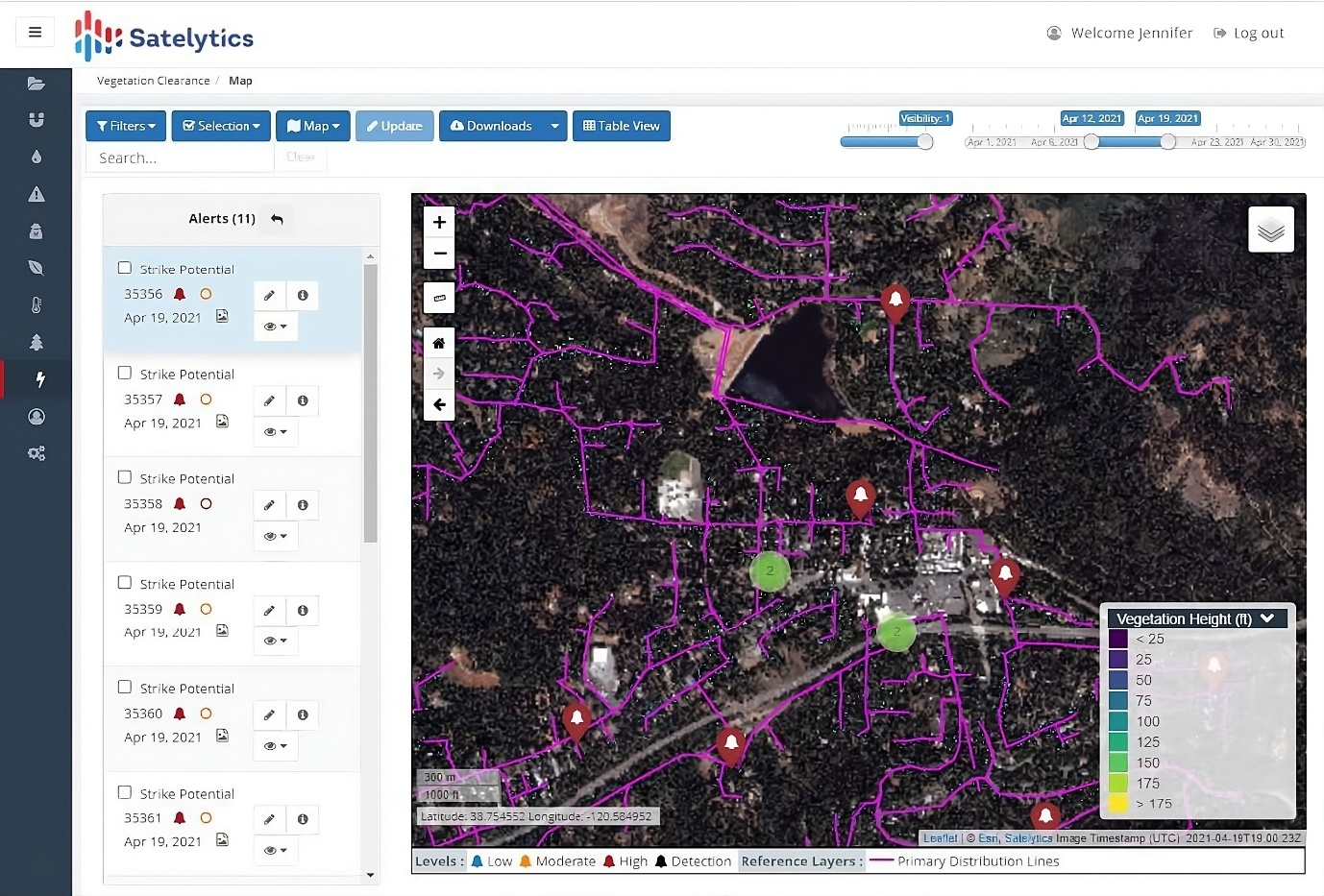

Satelytics is an AI-powered software that provides real-time monitoring and alerts for anomalies in your operations. It tracks changes in your assets, alerting you to potential risks before they become major issues.

By quickly identifying the source and severity of any potential problems, Satelytics helps you avoid costly consequences, environmental impacts, and reputational damage. It also helps you comply with regulatory requirements and maintain public trust.

With Satelytics, you can respond quickly to potential issues and direct your resources to where they are most needed. This helps you save time and money, while minimizing the risk of costly and reputation-damaging events.

Our specialty lies in the engineering, implementation, and troubleshooting of control system solutions that are tailored to meet the specifications of our clients.